Condé-sur-Noireau, France - 48° 51' 7" N 0° 34' 20" E

While we are reducing and lightening our Canmore footprint, the fabrication team at the Garcia shipyard has been working on the hull. Here are more pictures.

|

Firstly, the hull now has plates and the seams are welded shut. It also has a towing point at the stem. Seriously. |

|

Next, it also has portholes. This is how they start ... just tack welded in. |

|

| And this is how they are finished. Mmmm, brushed aluminium. This is how we expect the topsides (hull above the waterline) to be finished. |

|

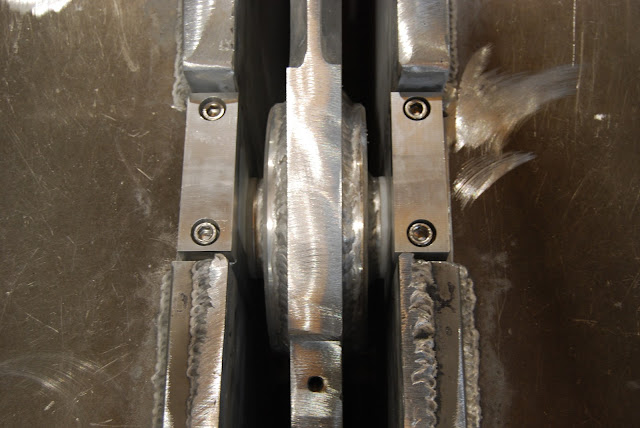

| Here, the worker is positioning the pivot into its cradle. |

|

| The very beefy pivot pin secured in place. |

|

| The interior of the hull, showing the solid welds to the ribs and stringers. |

|

| The aft (rear) skeg that protects the propeller shaft where it emerges from inside the hull. Worker standing next to the skeg (for scale). |

Progress!

We have been told the welding of the hull will be done by the time we arrive in France in mid-May.

Comments

Post a Comment